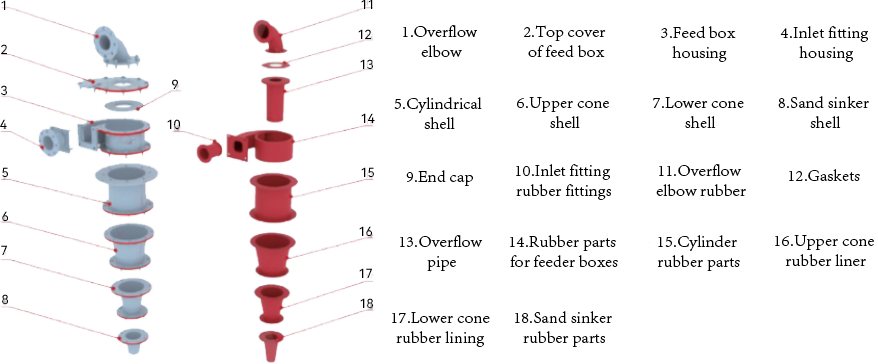

Slurry under pressure through the feed pipe along the involute direction into the shell, in the shell to do rotary motion, the coarse particles in the slurry or density of particles due to the larger centrifugal force and enter the periphery of the rotary flow, and ultimately discharged from the bottom of the sedimentation nozzle to become the sedimentation of sand; fine particles subjected to less centrifugal force, in the center of the rotary flow and with the flow of upward movement, and finally discharged from the overflow pipe to become the overflow.

The three-dimensional worm-shaped feeding structure realizes circumferential and axial feeding, eliminates the turbulence interference near the overflow pipe after the material enters the cyclone, accelerates the cyclone of coarse material to the direction of the bottom flow mouth, avoids the rapid rotation of the feeding material, and is more conducive to the enhancement of the classification efficiency.

Square tubular feeding form, so that the material is closer to the inner wall of the cyclone, the minimum resistance to feeding, so that the material has the greatest dispersion force, the least wear and tear on the feed box.

The most abrasion-resistant liquid-phase rubber liner available, providing a long life and greatly reducing cost of ownership, while maintaining your cyclone's internal runner shape and dimensions for a longer period of time, resulting in consistent classification efficiency.

The most resistant wet abrasive liquid phase rubber molded and cold bonded liners available for the longest service life.